Replacing an older boiler, especially one installed before 2005, is likely to involve changing the boiler flue. This is an important task which should always be carried out by a Gas Safe registered installer. For many installations it will be a skilled but relatively straightforward task, which is often included as part of the boiler installation cost. However, there are a number of boiler flue regulations which need to be considered and can on occasions make changing the boiler flue more challenging.

What Does a Boiler Flue Do?

In a modern fan assisted condensing boiler, the boiler flue could just as easily be described as an air/flue gas duct as it has two separate channels for gases and serves two functions:

- To expel the boiler’s exhaust gases into the outside air, where they are dispersed in the atmosphere.

- Bringing fresh air (oxygen) from outside the home to be used by the boiler to burn natural gas.

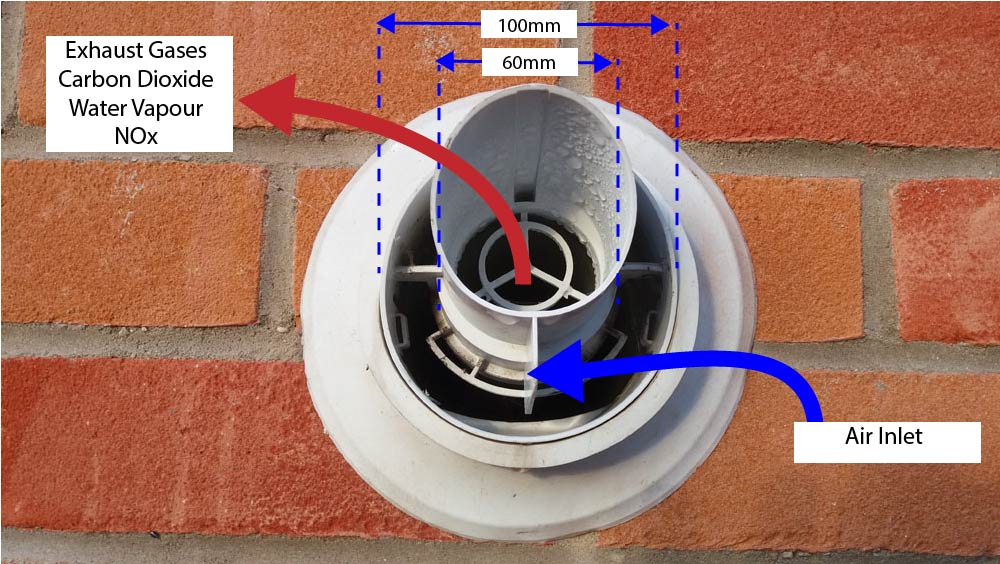

A typical gas boiler flue (or pipe to most people) has a diameter of 100mm, with two different channels for gases to flow. The 60mm central pipe is used to take the exhaust gases outside, whilst the 100mm outer ring is used to bring in fresh air.

The end of the flue is called the terminal and is the point where the exhaust gases are expelled into the atmosphere (as shown in the image above). Boiler flues of 125mm diameter are also used for longer runs of pipe.

Why Would I Need to Move My Boiler Flue?

The regulations and guidelines for boiler flue siting have changed significantly since condensing boilers were made compulsory in 2005. The tightening of the regulations has been done to improve safety and reduce nuisance to occupants, neighbours, and passers-by from condensing boiler flue exhaust gases. This means that the flue terminal, where the exhaust gases are released outside, cannot be as close to building elements such as windows, doors, roof eaves and other elements including parking spaces.

One other significant change is that guidance has been included for access for visual inspection of concealed flues so the entire length can be properly inspected for commissioning and annual servicing. This can cause disruption where the flue has been built into the fabric of the building and can be a particular challenge in flats where a shared flue system may be installed.

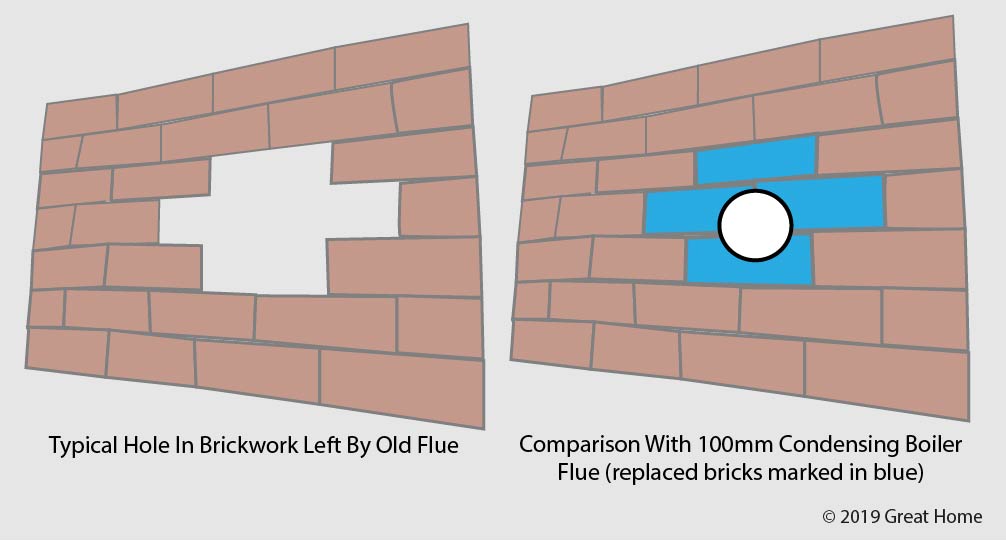

Even if the existing boiler flue position is suitable, the design of flues has changed over the years, with flue terminals generally being circular in shape with older non-condensing models being rectangular.

When replacing an older flue, a home could well be left with an odd shaped hole in the brickwork which needs to be made good. This could mean 3-4 bricks being replaced or worst case around 6-8 bricks. If the flue goes through the roof (a vertical flue) rather than a wall (horizontal flue) then other alterations may need to be made.

What Does Installation Of A Boiler Flue Cost?

For a straightforward horizontal flue installation, the cost would be around £200 for parts and labour including VAT. The basic flue kits for most popular boilers cost in the region of £100 and the rest of the cost is labour to drill through the brickwork and make good. This should be included in an installer’s price for a boiler replacement; if the boiler position is being moved then making good on the old flue may be quoted separately. Finding exact match bricks is a particular challenge although a local installer will usually have previous experience of where to find them.

For more complex and difficult installations the cost can increase significantly and could be closer to £500-£600. This would include constructing maybe six or seven metres of flue pipe round a number of bends and though a roof and making good the brickwork where an older rectangular flue has been removed. When working at height an access tower is required, which can cost £50-£100/week.

Where’s the Best Place For A Boiler Flue?

This does depend on the layout of a property, but a straightforward installation would be a wall mounted boiler using a horizontal flue which goes straight through a close outside wall either to the back or to the side of the boiler. There are various regulations around boiler flues, most of which are designed to ensure the exhaust fumes are widely dissipated into the atmosphere without creating risks to occupants and those walking past the property. The task of installing a horizontal flue can be simplified when the flue terminal (exhaust outlet) can be:

- At least 2.1m high, so there is no risk of hot exhaust gases coming into contact with people.

- Not sited under a car port roof or too close to a roof eaves.

- Well away from openings such as doors and windows to prevent exhaust gases from entering the building. Generally, with a fanned draught boiler, the terminal must be at least 300mm away from any opening.

- Sited a minimum 2.5m from a facing wall, fence, building, or the property boundary

There are other aspects that need to be considered, which your Gas Safe registered installer can help you with when they do a site survey.

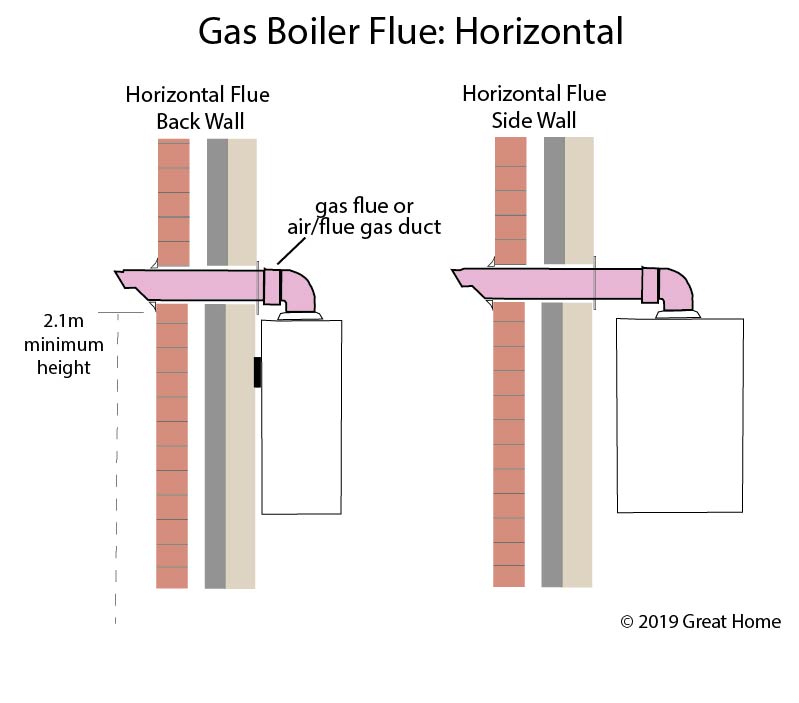

Horizontal Boiler Flue Layout

In the diagrams above, the horizontal flue goes through the inner and out brickwork of an outside wall. Whilst outside wall thicknesses do vary, mist manufacturers offer a telescopic flue, which can cope with reasonable adjustments in wall thickness. When installed, the flue is angled back slightly (a few degrees) to allow any moisture which condenses in the pipe to flow back towards the boiler.

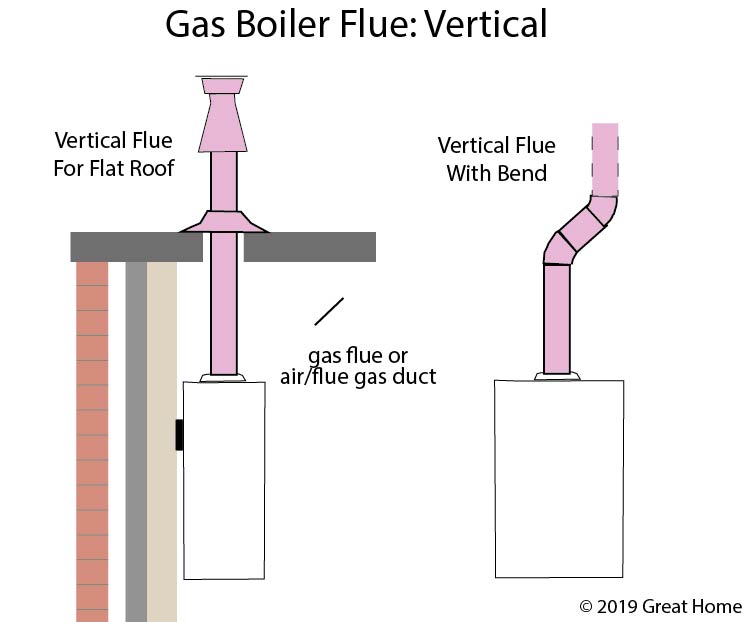

Vertical Boiler Flue Layout

Not every home has an outside wall suitable for mounting a flue terminal. In this case a vertical flue may be required, which is likely to go through the roof of a property.

Boiler manufacturers offer a variety of different flue bends which can be assembled to build different shaped flues. They also offer specialist components which can help solve particular challenges, such as a ridge tile with a pre-moulded hole for the flue.

General guidance is that the flue should be as short and as straight as possible.

Vertical boiler flues are a popular choice with singe storey homes such as bungalows.

When Would A Terminal Guard Be Used with A Boiler Flue?

Ideally the flue terminal is positioned where it cannot come into contact with people (i.e. above a height of 2.1m) but this is not always possible. In this case a flue terminal guard is used to prevent anyone from being burnt if they accidentally touch the hot flue terminal. The guard is a fine mesh with no sharp edges which provides at least 50mm clearance from the flue terminal. A flue terminal guard is used when the flue terminal is lower than 2m above the ground in an area where people could walk or when the flue comes up through a flat roof to which people have access. Depending on design, installation of a flue terminal would cost around £20-40.

Do You Need Planning Permission For A Boiler Flue?

Generally, you would not need planning permission for a boiler flue but there are a few instances where it could be required:

- A listed building. Check with your local planning authority whether consent is required.

- In conservation areas, World Heritage sites, national parks and areas of outstanding natural beauty the flue should not be fitted on the principal or side elevation if it can be seen from the road.

- The flue is on the rear of the building and extends more than one metre above the highest part of the roof.

Your Gas Safe installer should be able to advise you on this.

What About Shared Flues

Communal flue systems have their own set of requirements which a specialist installer should be able to help you with. A boiler linked to a communal system will generally need a flue gas non-return flap/valve to ensure that exhaust gases cannot re-enter the boiler

Why Is It Difficult to Find A Flue Solution for Blocks of Flats?

(Copy added in September 2020)

Gas boiler flues for blocks of flats are a problematic area, due to a combination of recent events which are conspiring to make things harder rather than easier for consumers, installers and manufacturers.

The events that have made this area more problematic are:

- The 2010 revision of Part J of the Building Regs placed much more emphasis on being able to visually inspect any joints in concealed flues, with inspection hatches. Flats built to older versions of the Building Regs were at the time not required to accommodate this level of inspection at construction stage.

- The 2018 Building Regulations ban on combustible materials on the external walls of buildings over 18m in height. For buildings of this height there are currently no commercially available flues which satisfy this requirement, as they tend to use plastic on the inner lining to avoid leakage of exhaust fumes.

- The plan to prevent gas connections to new build homes from 2025

- Leasehold flats often have restrictions on what changes can be made to the external walls. This may require the managing agents to give their approval on any flue solution.

The knock on effect of these is that gas boiler manufacturers are having to develop new post-Grenfell flue solutions for flats whilst being aware that gas boilers currently will not be installed in new homes from 2025. To add to the challenge, older apartment blocks struggle to meet the 2010 Building Regulation when gas boilers are due to be replaced.

On high rise flue systems, there is currently a consultation being undertaken by the Ministry of Housing, Communities and Local Government. Input to this consultation closed in May 2020 but as of yet there has been no response from the Ministry. Once the response is published then boiler manufacturers will be in a better position to identify possible solutions but this may take some time before any products are commercially available. Link to consultation: https://www.gov.uk/government/consultations/review-of-the-ban-on-the-use-of-combustible-materials-in-and-on-the-external-walls-of-buildings

What Regulations & Guidelines Cover Boiler Flues and Boiler Terminals?

There are three main documents which would influence flue design and terminal location:

- The Building Regulations Part J (2010 incorporating 2013 amendments)

- British Standards BS 5440-1:2008

- Guide to the Condensing Boiler Installation Assessment Procedure for Dwellings (ODPM 2005)

The Building Regulations would be the main reference for Gas Safe installers. British Standards requirements are broadly included in Building Regulations although the document includes additional aspects such as shared flues across multiple floors in flats.

The OPDM guide considers some of the other challenges of replacing a non-condensing boiler with a condensing boiler. As an example: “The flue gases discharged from the flue terminal are cooler and less buoyant, and usually form a visible ‘plume’. They may cause wetting of surfaces too close to the terminal, or nuisance to neighbouring property, or people passing nearby.”

View the latest version of Part J of The Building Regulations.

Do I have To Move My Existing Boiler Flue If It Projects Onto My Neighbours Land?

When replacing an old gas boiler with a new one, you will need to comply with the current Building Regulations. This requires the flue outlet to be at least 600mm from a neighbouring property.

You are not necessarily required to move an existing flue for an older boiler that is still in use, that projects onto a neighbouring property, provided the installation met the building regulations at the time, was installed with the neighbour’s permission and has been there at least 20 years as you may have established a “prescriptive easement”. See https://www.gov.uk/government/publications/easements-claimed-by-prescription/practice-guide-52-easements-claimed-by-prescription

Guide prices last updated: April 2019.