Air Source Heat Pumps (ASHP) have been suggested as a potential alternative to gas boilers for space and water heating. Whilst currently used mainly for heating properties with no gas connection, the UK Committee on Climate Change (CCC) and the draft Future Homes Standard have even proposed banning gas boilers in new build homes from 2025, by not allowing a natural gas connection.

Types of Heat Pumps and Basic Principle

Heat pumps are designed to absorb heat from an external heat source and use it for space and water heating in the home. The external heat could be taken from the:

- Air (from outside air)

- Ground (usually from a pipe buried in a horizontal trench or a vertical borehole)

- Water (using a flowing river or open water)

Generally heat pumps heat water for use in space and water heating in the home and in this article a mention of an air source heat pump refers to an air-to-water heat pump. Not covered in this article are air-to-air heat pumps which directly deliver warm air to each room, rather than using room radiators. These have attracted greater interest in recent years, although a separate solution is then required for hot water heating.

A heat pump can be used to extract far more energy from the heat source (the air, the ground or a body of water) than it consumes. Heat pumps are measured according to their coefficient of performance or COP (sometimes CP or CoP) and typically produce a COP of 2.5-3.5. That means a heat pump using 1 kWh of electrical energy can deliver say 3.0 kWh of heat, making it competitive in the right circumstance with fossil fuel sources that may initially appear cheaper per kWh.

The average energy gains over the year are often described as the Seasonal Performance Factor (SPF). For a well installed ASHP a typical SPF for space heating would be 3.0 with a performance for water heating at 2.3. This is because water heating requires a higher temperature to be achieved, upwards of a 55°C gain, and the ASHP is less efficient when delivering these higher temperatures. In comparison, space heating can be operated with lower temperature gains, typically 35°C.

At March 2019 prices, domestic electricity was circa £0.18/kWh with gas at circa £0.04/kWh, meaning that a heat pump would have to deliver an SPF of above 4.5 to deliver a cost benefit on operating costs. If fossil fuel prices rise faster than electricity in the future (driven by higher gas prices or a carbon tax?) this would deliver a cost benefit at a lower COP. One off installation costs also need to be taken into account; it is much easier to do a new installation in a new house than change an existing gas boiler central heating system to use a heat pump.

To calculate the running costs of an installation at different energy prices see Air Source Heat Pump Running Costs Calculator.

| Air and Ground Source Heat Pumps may be eligible for the Renewable Heat Incentive (RHI) which pays incentives, for seven years, for those using renewable heat. (Read Ofgem’s Essential Guide For RHI applicants). To be eligible the system would have to be installed and registered by an MCS certified installer. It closes in March 2022 for domestic installations. |

Why Air Source Heat Pumps (ASHP)?

Air source heat pumps are generally cheaper and easier to install in the home than ground or water source heat pumps although their “Seasonal” COP will be lower. This is because in winter using the ground or flowing water as a heat source gives access to warmer and more consistent temperature than the air. All three types of heat pump are best installed in new homes that are well insulated, where space heat demand is low. Ground source heat pumps can be costlier to install and require the drilling of a deep borehole (typically around 20-50m in depth but can be deeper). Pipes can also be laid in shallow trenches but that requires a much larger area of land, not available to the average home. Water source heat pumps are associated with large bodies of water such as a lake or river and again these are often not accessible for the average home. Due to the much higher capital cost, ground and water source heat pumps are better suited to larger systems that serve a number of homes or a commercial building.

A Typical Air Source Heat Pump System

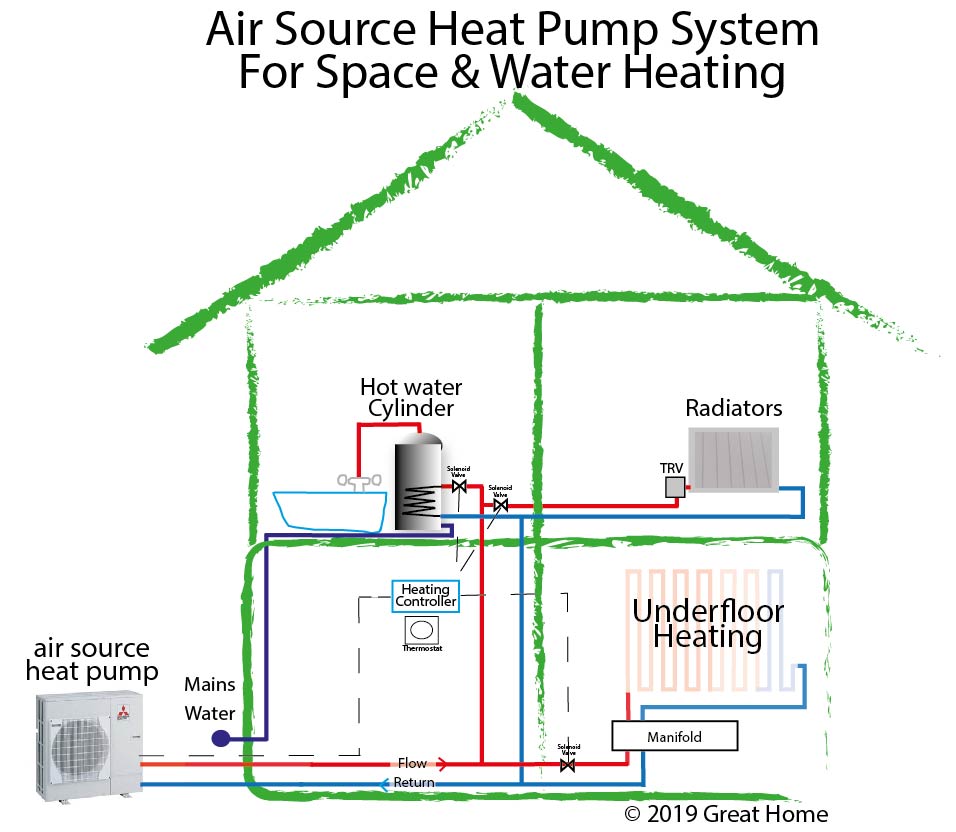

The ASHP itself looks much like a stand-alone air conditioning unit (see simplified image) and sits on the outside of your home. Like a gas boiler it provides heat to supply hot water and space heating. Not shown in the image are the control systems used to manage the heat flows to the space and water heating. The operating noise of the ASHP is relatively low but it is wise not to position it near an open bedroom window.

Image courtesy of Cool Energy

To reduce system cycling and improve efficiencies some manufacturers and installers will sometimes recommend use of a 60-100 litre buffer tank to increase the heated water in the heating system. This means that a flow of water is available, even when the ASHP is not operating. The ASHP can continue to run for a few extra minutes, even when there is no call for heat from space heating or water heating, which reduces system cycling. Buffer tanks are more likely to be recommended in larger houses with many separately controlled heating zones.

Differences From A Gas Boiler

Heat pumps work most efficiently when delivering a flow of water at around 35°C, rather than the 60°C typically delivered from a gas boiler. As the water temperature is lower, radiators need to be larger than those used for gas boilers. Typically you would need double the radiators if operating a system at Δt30 such as a heat pump rather than at Δt50 as produced with a gas boiler. Pipework also needs to be bigger, as flow rates are higher to compensate for the lower water temperature. Underfloor heating, which needs a much lower temperature anyway, is a good option if it can be installed as part of the concrete floor slab. These differences make it generally more cost effective to install a heat pump in a new home, rather than having to change over an existing gas central heating system, However, if a house with an existing gas boiler has been upgraded with better insulation then the overall heat demand will be lower and will make an air source heat pump more attractive.

With a heat pump it is best practice to leave the system on for longer, as the instantaneous heat output is lower than for a gas boiler. The home will require more time to get to the desired temperature from cold than a gas boiler. Provided this is accounted for, the home can be as warm as with a gas boiler. On a cold day the ASHP heating may be on continuously, rather than the intermittent bursts delivered by a gas boiler. Experience has shown that leaving heat pumps on continuously generally gives the lowest running costs, as heat pumps work best when they are delivering lower temperatures. With a gas boiler, a radiator may be at 60°C, whereas with an ASHP it could be 20°C cooler.

Air source heat pumps are installed outside the home, so there are some considerations related to where the pump can be mounted (no closer to the property boundary than one metre) and to avoid visual intrusion (particularly in listed buildings).

During frosty weather the system will occasionally have to go into a defrost routine to avoid ice build up on the heat exchanger.

Air Source Heat Pump Output Compared To Gas Boiler

Domestic ASHPs are typically available in the 4-15kW output range, compared to 12-30kW output for gas boilers.

Heat pumps are most suited to installation in better insulated quality built homes that demand lower heat output. That said, people are most suited to well insulated quality built homes as well! It is smart to make your home as energy efficient at possible before you decide on the type and size of a space heating system.

Typical Peak Space Heating Demand Of A Home

Whilst it is hard to be specific, the table below shows typical levels of peak space heating demand required to maintain a 21C inside temperature when the outside temperature is -1 C.

| Description | Typical space heat demand per m² of floor area | Heat demand for 3-bedroom house (100m² floor area) | Heat demand for 4-bedroom house (150m² floor area) |

| Passivhaus | less than 10W/m² | 1kW | 1.5kW |

| New home (high level of insulation) | 40W/m² | 4kW | 6kW |

| Older house (poorly insulated) | 100-150W/m² | 10-15kW | 15-23kW |

Air source heat pumps could provide heating for a wide range of different homes, although would struggle with poorly insulated larger homes. With Passivhaus , space heating requirements are minimal and many occupants would never need the space heating on at all.

Water Heating With A Heat Pump

As heat pumps operate at lower temperatures than gas boilers, stored water may only be heated to around 50°C. This is often fine for household use but to ensure there is no risk of Legionella build up (a type of bacteria) an immersion heater is used once a day to heat the whole tank from 50°C to 60°C.

Air Source Heat Pump Costs: Typical New System Installation

The table below shows the total cost to the builder of installing an air source heat pump system versus a gas boiler system (both systems using a hot water cylinder and radiators), based on 2020 prices (see Centre for Sustainable Energy report: Cost of carbon reduction in new buildings )

| Home type | Air Source Heat Pump System Cost | Gas Boiler System Cost | Difference |

| Detached house | £9,200 | £7,750 | +£1,450 |

| Semi-detached or terraced house | £8,000 | £5,500 | +£2,500 |

| Low rise flat | £6,400 | £5,600 | +£800 |

Air source heat pump costs for a new installation are higher than for a gas boiler (between £800 and £2,500 depending on house type). This is primarily down to the costs of the heat pump itself versus a gas boiler. The table below shows indicative pricing available from UK plumbers merchants for a typical gas boiler and for different power output heat pumps.

| Heating type | Typical price |

| Gas boiler 12-30kW | £750 – £2,000 |

| 5kW Air Source Heat Pump (Vaillant Arotherm) | £3,400 |

| 6kW Air Source Heat Pump (Grant AERONA3) | £3,400 |

| 8kW Air Source Heat Pump (Vaillant Arotherm) | £3,800 |

| 10kW Air Source Heat Pump (Grant AERONA3) | £4,900 |

| 11kW Air Source Heat Pump (Vaillant Arotherm) | £4,400 |

| 15kW Air Source Heat Pump (Vaillant Arotherm) | £5,900 |

| 16kW Air Source Heat Pump (Grant AERONA3) | £5,900 |

As well as the heat pump or gas boiler, other items used in the system will include a hot water cylinder, costing between £750-£1,500 depending on storage capacity (usually 150-330 litres), and radiators for each room. Radiators for the heat pump system will tend to be sized to be a little larger than for a gas boiler system, as the system operates at lower temperature (35°C rather than 60°C). Pipework will also have to be bigger to allow for greater flow rates. However, heat pumps are ideal for use with underfloor heating which, although more expensive to install than radiators, does free up wall space and also delivers a more even temperature throughout the room. The other components of the two systems are similar in costs and installation time (pipework, controllers and control valves).

Typical Cost Of Replacing An Existing Gas Boiler With An Air Source Heat Pump System

Deciding whether to replace an old gas boiler with an air source heat pump depends on a number of factors. If you own an old draughty home which costs a lot to heat then installing decent levels of insulation and cutting down on draughts would be essential. Ideally, for the ground floor, underfloor heating would also be used, rather than increasing the size of the existing radiators.

The table above shows that the air source heat pump is likely to be circa £2,000 more expensive than the gas boiler but there are other factors to take into consideration. If the boiler is quite old then there may be other parts of the system that also need to be upgraded (see table below) as gas safety regulations change over the years.

| Other potential upgrades required | Approx Cost |

| New condensate pipework (if old boiler is not a condensing boiler) | £150-£250 |

| New gas flue | £200-£500 |

| Replace gas supply pipe (if supply pressure insufficient) | £150-£300 |

A site survey would need to be done by a Gas Safe Registered Installer, to identify if any or all of this work needed doing.

Upgrading of any electrical wiring, the hot water cylinder and the control system will probably need to be done with either a replacement gas boiler or a heat pump. A key question to answer is whether the radiators are of sufficient size to heat the room using the lower water temperature provided by the heat pump. If not then these will need to be upgraded in size. Pipework with an increased diameter will also be needed. It may be smarter to spend the money on upgrading the insulation in your home, reducing the energy required to heat each room; in this case the old radiators and pipework may then be suitably sized to heat the better insulated room with a heat pump.

Boiler Upgrade scheme

In October 2021 the UK government announced a Boiler Upgrade Scheme to help householders changing from a gas boiler to a heat pump (air source or ground source). The £450 million scheme will run for 3 years and offers a payment of £5,000 per home towards installing a new heat pump. The scheme is scheduled to open in April 2022. The application process for the payments has yet to be announced.

Warranty

Air source heat pumps have warranties of 3-5 years. If a new hot water cylinder is required these often come with a 25-year warranty.

| Product | Warranty Period |

| Vaillant Arotherm | 5 years |

| Grant AERONA3 | 5 years* |

*when installed by a G1 installer. Subject to T&C’s

Air Source Heat Pump Maintenance

To qualify for RHI payments and to maintain warranty on the product the system should be serviced annually by a MCS certified installer. The ASHP maintenance would include:

- Cleaning filters

- Checking glycol levels

- Check manifolds on underfloor heating

How Do I Find An Installer For An Air Source Heat Pump System?

Feedback from those with heat pump already operating indicates that the quality of the design and installation of the system are key to getting an effective system. There are a variety of routes to try when searching for an installer. One option is to use the Renewables Guide Quote Service. Great Home may receive affiliate fees for your use of the Renewables Guide Quote Service. Alternatively you can find individual Microgeneration Certification Scheme (MCS) certified installers by visiting the MCS website.

Having had an ASHP fitted in 2020 I can tell you with certified experience and evidence it was one of the worst options we could have taken to heat our house.

We do have an older type house with four beds, triple glazing, and insulated loft.

The performance of the ASHP falls far below the sales pitch and expectation on which it was sold and installed. However the biggest shock was the cost of running our Mitsubishi unit, our electric bill when running our oil boiler and the rest of the house was around £90 per month, add the oil in the winter at around the same cost, we were paying in the midst of cold winters under £200 a month.

Enter the ASHP sold and fitted by Greener Living ltd. Cost of fitting and unit £15000, OK we thought for helping the planet and getting what we were told a lot more heat for our money. After the first month our electric bill went from £90 to £470 yes you read that right, that was before it got really cold, it was November, our electricity on a monthly basis was unbelievable. Greener living really did not want to know, they had been paid, they did tell us that in the next few months the government were going to reduce the cost of electricity dramatically to anyone that had taken a Green option of heat pumps, that was total B/S.

So our annual electric bill went from £1100 a year to almost £5000 a year, how is that going Green. To assist in warming of the property e have also had to install a Log Burner to help warm the house.

We are now looking to have the system taken out and replaced with a LPG boiler, that will be warmer and cost a lot less to run

You have our true statement of facts, Please consider all your options before going green, it is an expensive way to live.

John, you have my sympathy: that sounds incredibly painful. But the fault is not with the heat pump!

Installing a heat pump is more expensive than installing a boiler, but the running costs should be very comparable – the heat pump should be slightly cheaper. Why? Because, very roughly electricity is 3 x the cost of gas but heat pumps produce typically 3 units of heat for 1 unit of electricity. This is based on my experience and on that of thousands of others.

What you have is a *badly installed* heat pump and your complaint should be with the installer.

With sympathy and best wishes

Michael

Very helpful. We live in a 1875 3 story semi-detached house in central London. We had central heating installed in 1987 this is radiators in the 5 bedrooms and siitting room with underfloor heating in the kitchen and conservatory. The loft is fully insulated and there is double glazing on all windows and oudsite doors.

In 2007 we changed to a Viessman condensing Boiler plus installed solar hot water with a new hot water cylinder fed from the solar below and the gas boiler above. In 2010 we installed 12 solar PV panels generating 4.2 kWh (with a feed in tarrif). We are palnning to install a solar battery.

Our mean annual dayly electricity consumption is 6.7 kWh.

We will need to be carbon neutral in the near future.

I am thinking of installing a 7kWh battery – however if we replace the gas boiler with ASHP for both CH and hot water what size battery should I install?

With an ASHP will I need to change the pipes to the radiators?

Hi Isky,

A key driver would be your home’s specific demand for heating energy. Assuming your home isn’t exceptionally different in terms of thermal insulation, the typical house in the category described would use circa 30,000 kWh of gas energy to heat annually, most of it in the winter months for space heating. Even assuming a better energy performance for your own home, it is likely that on colder days (around freezing) then daily usage could be circa 100 kWh of gas which would equate to circa 30kWh of daily electricity usage with an Air Source Heat Pump. This would dwarf most domestic storage batteries currently available.

If switching to an ASHP then it will depend on the output of existing radiators and the pipes that supply them. The supply temperature of the hot water for a heat pump is significantly lower than for a gas boiler. So the output of the radiators has to be bigger and the flow rate through them has to be higher. Since many installed radiators are already higher output than needed this may not be a problem. Also if the room is now better insulated then before, then the existing radiators and pipework may be able to cope with the lower water temperature. The best approach with heat pumps is to insulate very well to reduce heat loss as much as you can.

I appreciate this doesn’t solve your battery size question but I hope this at least helps your thinking on the challenge.

Kind regards

Jon

Hi, very informative and unbiased article, a huge thank you.

My take away is that we need to see 10x increase of gas price before gas boilers become to expensive to run and it becomes more financially viable to run heatpump.

I am keen to understand costing, I use in rough estimate 25k – 28k kWh Gas / year.

The mid terraced house was redesigned with more insulation and key to this discussion, underfloor heating on both floors with porcelain flooring.

I looked at the numbers and could not figure how heatpump would be cheaper to run and heat the house (installation a side), this is based on that electricity cost much more than Gas and given that heatpump use electricity I can’t see how this would be less costly?

It is mentioned about piping, does all piping in the house need to change? (including the underfloor pipes?). Maybe I misunderstood part of the blog/article.

Hi Essa,

Thanks for the feedback and questions. It can be a challenge to adapt an existing home with a gas boiler to use a heat pump but hopefully my response can point you in the right direction.

In my view, a heat pump provides a possible space and water heating solution for those with very well insulated homes. Before considering a heat pump, your high level of gas usage would need to be reduced by improving the building fabric to reduce heat loss. This involves a combination of improved insulation together with considering how to reduce ventilation heat loss through floors, ceilings, walls, windows and doors. To read more on this see: Reducing Greenhouse Gas Emissions From Energy Used In UK Homes.

Annual running cost calculation

Whilst I wouldn’t recommend putting a heat pump in, until the building fabric had been dramatically improved, let’s take a look at the financials if you did so. A few assumptions are needed. Let’s assume that your annual use of gas of 25,000 kWh is made up of 20,000 kWh for space heating and 5,000 kWh for hot water heating. Assuming a seasonal performance factor for the heat pump of 3 for space heating and 2.3 for water heating means the heat pump would consume 8,840 kWh of electricity annually i.e. for each kWh of electricity on average you will get 2.83 kWh of heat energy. For simplicity I have taken some standard gas and electricity tariffs from one of the bigger energy companies, EON. The particular tariff, for the UK Midlands, has prices of: Electricity 18.732p per kWh, Gas 3.318p per kWh and a gas standing charge of 26.6007p per day. All prices include VAT at 5%.

Sticking with a gas boiler gives an annual cost of: 25,000 kWh * 3.318p + 361 * 26.007p = £829.50 + £97.09 = £926.59.

Switching to a heat pump allows you to save the gas daily standing charge so the annual cost would be 8,840 kWh * 18.732p = £1,656.02.

So you would pay £729 per year more for the same level of heating (79% more).

However at the moment the UK government applies a carbon tax to electricity generation but not to gas usage. With carbon emissions falling rapidly over the last decade this means that lower carbon electricity is financially penalised compared to gas (and coal). If the UK government applied a similar level of carbon taxes to all fuels then the gap would close. Depending on the level of carbon taxes applied (£100 per tonne of CO2 has been mentioned in the past) then this cost gap would not exist. The historic subsidising of gas compared to electricity is a political decision. To change it would potentially impact on fuel poverty which is why governments have been reluctant to act.

The balance between gas and electricity prices would certainly have to change, but not by the 10x level you mention.

Installation Costs

Better insulated homes require smaller boilers and smaller capacity heat pumps, making replacement installation costs generally lower in both cases. So its always best to improve insulation first and then replace the boiler with a smaller capacity unit. Gas boilers deliver hot water to wall mounted radiators at around 60C compared with a heat pump at 35C. So to deliver the same amount of heat to a room require radiators that are bigger (as the water in them is cooler) and a greater flow of heated water. Whether existing pipework needs replacing depends on whether they can cope with the higher flow rate (in many cases they can). Underfloor heating is ideal for use with a heat pump as hot water supplied to underfloor heating needs to be much cooler than that supplied to a radiator. So these would not need replacing.

Hope this helps.

Kind regards

Jon

Hi Jon

I want to apologise i never got in touch. I found your response very informative. However, I think much has changed due to increased cost of Electricity and Gas which is

considerably higher since you wrote your response.

In terms of heat loss, I recently re-roofed the house with insulation in the roof (both floor and roof) this was to ensure minimum heat loss and there has been a huge improvement (middle of winter and cold snap) as heat loss has decreased.

In summary, taking your assumption at this point in time, it is not efficient enough to move from Gas to Heatpump given the high cost of installation and the huge increase in Electricity cost based on my calculation, yet I might get my numbers wrong.

However, UK government might bring new initiatives which will make it more affordable to install Heatpumps.

Hi There,

Thank your for this very useful article.

Can I ask, is an air to air heat pump a better solution for a 1970s property that is using an economy 7 immersion heater for water and a gas boiler only for the radiators?

I.e. ditch the central heating and stick with the hot water system, I am also planning to add solar panels and have surplus electricity generated heat the HW tank.

I will also be getting some consultation on insulation too (current EPC rating is D)

Thanks again

Iain

Hi. Thanks for the nice summary.

1. Thank you for being specific but in your table “Typical Space Heating Demand Of A Home” you didn’t say what demand that heating power applies to? i.e. is that with 10 °C of temperature difference between inside and outside.

2. You didn’t mention air to air heat pumps i.e. air conditioning.. Using a small heat pump for DHW and then abandoning radiators and using AC to heat and cool a house seems smart to me. This avoids the need to heat water to 55 °C in order to maintain a room at 20 °C using radiators.. So I would expect improved COP due to the low delta T.

Michael

Hi Michael,

Thanks for the the feedback. To clarify/comment:

1. The typical space heating demand table shows peak space heating. In the UK this effectively means the power required to maintain a 21C inside temperature when the outside temperature is -1 C. I have added this to the table description as it wasn’t clear. It really comes from the Passivhaus standard where, to qualify for the standard, peak demand should be no more than 10W per m2.

2. I would agree with your view on the potential for air-to-air heat pumps. They are starting to emerge as one of a number of options for the future decarbonisation of UK homes and were mentioned in the MHCLG January 2021 response to the 2019 consultation on the Future Homes Standard. However they are at a few disadvantages initially (such as the need for an additional water heating solution) which means that suppliers of the technology will need to make a big effort to establish themselves in the domestic retrofit market. They do require a very different mindset from installers and so far the visibility has been at a very low level (even lower than air to water heat pumps). I will add a brief mention of them to my piece. For new build it is easier but then if we were building decent fabric first homes then we probably wouldn’t even need space heating!

I appreciate you taking the time to comment.

Kind regards

Jon

If I have to have larger diameter pipes – all rad pipe work is hidden .in the walls :

Does that mean they will have to rip out the old pipe which entails tearing all walls , plaster and then replastering all walls after? As u got upstairs . ??

Potentially yes, either repacement or new pipes run in parallel with what you already have. Existing central heating systems vary a lot in how much slack there is in the design, and older ones that have been converted from single pipe to twin piping may already have suitable size. Microbore however is likely to need total replacement. It is unusual to have plastered in pipework for all of the system, and it may be easier to run new pipework over the surface to avoid too much disruption..